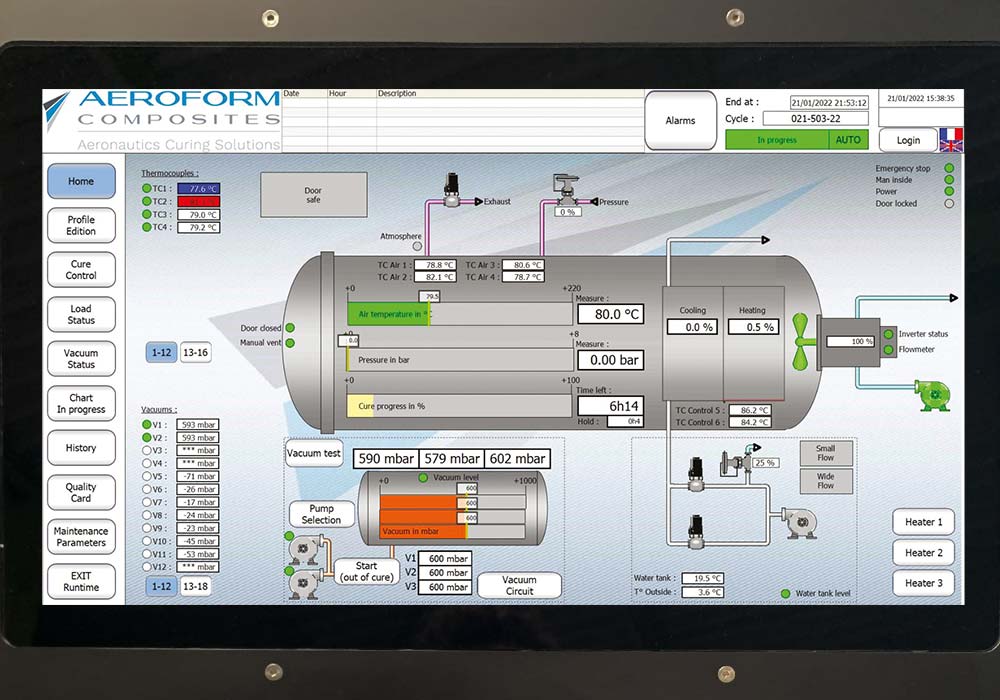

Autoclave Control System

Aeroform has developped a control sytem for autoclaves : AFACS – AEROFORM FRANCE AUTOCLAVE CONTROL SYSTEM

AFACS is a control system developed on the Siemens WinCC software platform, combined with a Siemens PLC. It is the most suitable solution for production autoclaves in the aerospace industry.

This control system can be integrated into all types of autoclaves, with no limitation on the number of parts to be managed, and allows the generation of customized reports.

Quality and maintenance modules are also included.

The Advantages of AFACS

The advantages of the Aeroform control system:

-

Highly intuitive supervision interface, tailored to each user: maintenance, production, and operators

-

Multiple control modes: dynamic, hottest/coldest point temperature control

-

Excellent regulation of your curing cycles

-

Reduced curing times

-

Supervision based on Siemens PLC, approved by major aerospace OEMs

-

Quality module for detailed analysis and fast cycle validation

-

Improved traceability of curing cycles for aerostructure parts

-

Multi-part loading capability

-

Fully compliant with NADCAP standards

Why retrofit your autoclave?

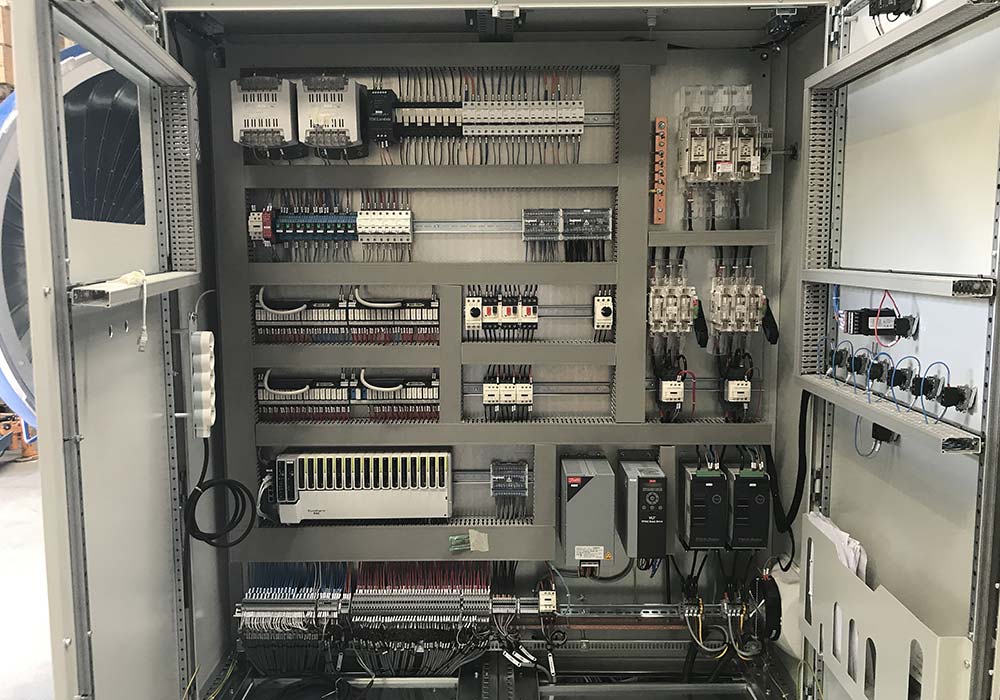

Replacing your power and control cabinet allows you to secure your process and bring your equipment back into electrical compliance. Choosing a retrofit ensures the continuity of your curing cycles for the next 20 years.

Aeroform offers complete retrofit solutions for your autoclaves, including:

-

Replacement of the power cabinet

-

Installation of a new high-performance control system: AFACS II

With a retrofit, you can significantly improve the productivity of your equipment while avoiding the investment in a new machine.

Key Steps of an Autoclave Retrofit

Our teams provide a turnkey solution that includes the following steps:

-

On-site survey of your electrical schematics

-

Electrical study and programming

-

Manufacturing of the new electrical cabinets

-

Rewiring of the electrical cabinets at the customer site

-

Commissioning of the new autoclave control system

-

Final acceptance with your parts

Aeroform then provides all the technical support needed to optimize your curing cycles and ensure the long-term reliability of your process.

Our teams remain available during your production shutdowns to carry out the retrofits, minimizing the downtime of your autoclave.

Improve Your Autoclave Performance During Retrofit

Our highly qualified teams support you with customized solutions tailored to your production constraints.

We provide expert advice and technical innovations to optimize the efficiency of your autoclave.

Examples of possible optimizations:

-

Increase in the number of vacuum lines

Allows more parts to be loaded into the autoclave, thereby increasing your production capacity. -

Addition of part thermocouples

Improves monitoring and control of curing cycles. With our expertise, your cycles can be directly controlled via the part thermocouples, ensuring optimal uniformity. -

Integration of a variable-speed fan drive

Particularly useful for low-temperature curing (±50 °C), this system improves cycle precision while reducing energy consumption.