High-Quality Technical Support

Aeroform benefits from a team of technical experts dedicated to ensuring optimized production and continuous support.

From installation to the requalification of your autoclave vessel, we provide a turnkey, reliable, and long-term solution.

Aeroform Composites offers a structured, responsive, and highly qualified autoclave maintenance service, dedicated to all brands of autoclaves.

Proven Expertise for Maximum Reliability

Our technical teams, trained to meet the most demanding standards of the aerospace industry, operate under both preventive and corrective maintenance contracts.

Each intervention aims to guarantee safety, regulatory compliance, and high performance of your autoclaves

Autoclave Maintenance Contract

PREVENTIVE AUTOCLAVE MAINTENANCE

Each service intervention is scheduled according to your production agenda for all types of autoclave brands and includes the following:

-

Inspection of the autoclave heating system

-

Operation check of the door

-

Verification of safety systems

-

Inspection of the vacuum system (pumps, valves, etc.)

-

Electrical checks

A strong commitment to supporting your production equipment.

Choosing Aeroform as your autoclave maintenance partner ensures controlled production. With our recognized expertise, technical know-how, and quick response capability, we help you minimize technical risks and secure your industrial commitments.

Subscribe to our autoclave maintenance contract

Contact us now to set up your autoclave maintenance contract.

Metrological inspection, calibration,

and thermal survey of your autoclaves

Ensure the reliability and accuracy of your manufacturing processes with AEROFORM’s metrology and calibration services.

Our qualified technicians perform on-site inspections to verify, calibrate, and map your manufacturing equipment.

We monitor the key parameters of your Autoclave :

-

Temperature

-

Pressure

-

Vacuum

Each intervention is accompanied by a detailed report, including the results and any adjustments made.

Our instruments are traceable to recognized metrological standards (COFRAC, UKAS, etc.), ensuring the traceability and compliance of your equipment.

With regular monitoring, you maintain optimal performance, extend the lifespan of your installations, and remain compliant with quality standards (AMS2750, NADCAP, ISO 9001).

Thermal Survey of your Equipment

Thermal mapping is essential to ensure temperature uniformity within your equipment (autoclaves, ovens, etc.).

It helps identify cold or unstable zones, adjust your production cycles, and guarantee consistent process quality.

AEROFORM technicians perform these operations directly on-site using measuring instruments traceable to recognized metrological standards (COFRAC, UKAS, etc.).

We work on all brands and types of autoclaves and provide a detailed thermal mapping certificate after each intervention.

For greater efficiency, this service can be combined with calibration or preventive maintenance, helping you optimize costs and maximize equipment availability.

Need a ten-year requalification for your autoclave?

Our experts provide customized solutions suited to your production environment. Get in touch today for a quote on your autoclave requalification.

Ten-Year Requalification

We provide a team of specialized technicians to carry out the ten-year inspection and/or acoustic emission testing on all types and brands of autoclaves, in partnership with CETIM, a recognized reference in the acoustic requalification of pressure vessels.

Why choose acoustic testing?

This non-destructive, real-time method offers several key advantages:

-

Early detection of developing defects

-

Precise localization of damaged areas

-

Enhanced prevention of industrial risks

-

Reduced machine downtime (1 week instead of 3 weeks with hydraulic testing)

Acoustic test for Autoclave

These regulatory inspections are carried out by Aeroform and CETIM

(COFREND Level 2 or 3 certified). We perform all necessary tests to issue certifications that ensure the compliance of your industrial autoclaves.

Authorized bodies, such as APAVE, recognized by the Ministry of Industry, are qualified to approve acoustic emission requalification, provided that the technical file is complete and compliant with current regulations and that the test results are satisfactory.

Spare Parts for Autoclave

Reliable solutions for the maintenance of your equipment

Need to replace a defective part on your industrial autoclave?

Aeroform Composites offers a large stock of spare parts compatible with all brands and types of autoclaves, ensuring the continuity of your production.

General components

-

Door seals (flat, profiled, custom)

-

Valves, compatible with fluids and gases used in autoclave cycles

-

Components for the vacuum system

- Phenolic traps

-

Vacuum Hoses : HoseVac

-

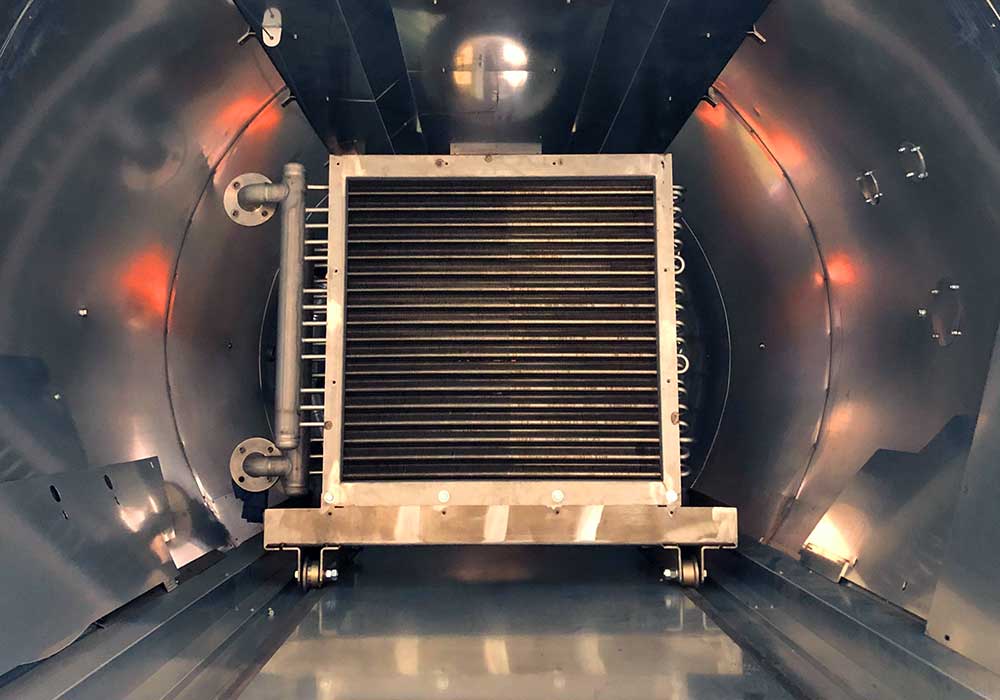

Heating elements and radiators

-

Electrical resistances of all power ratings and configurations

-

Heat exchangers for cooling